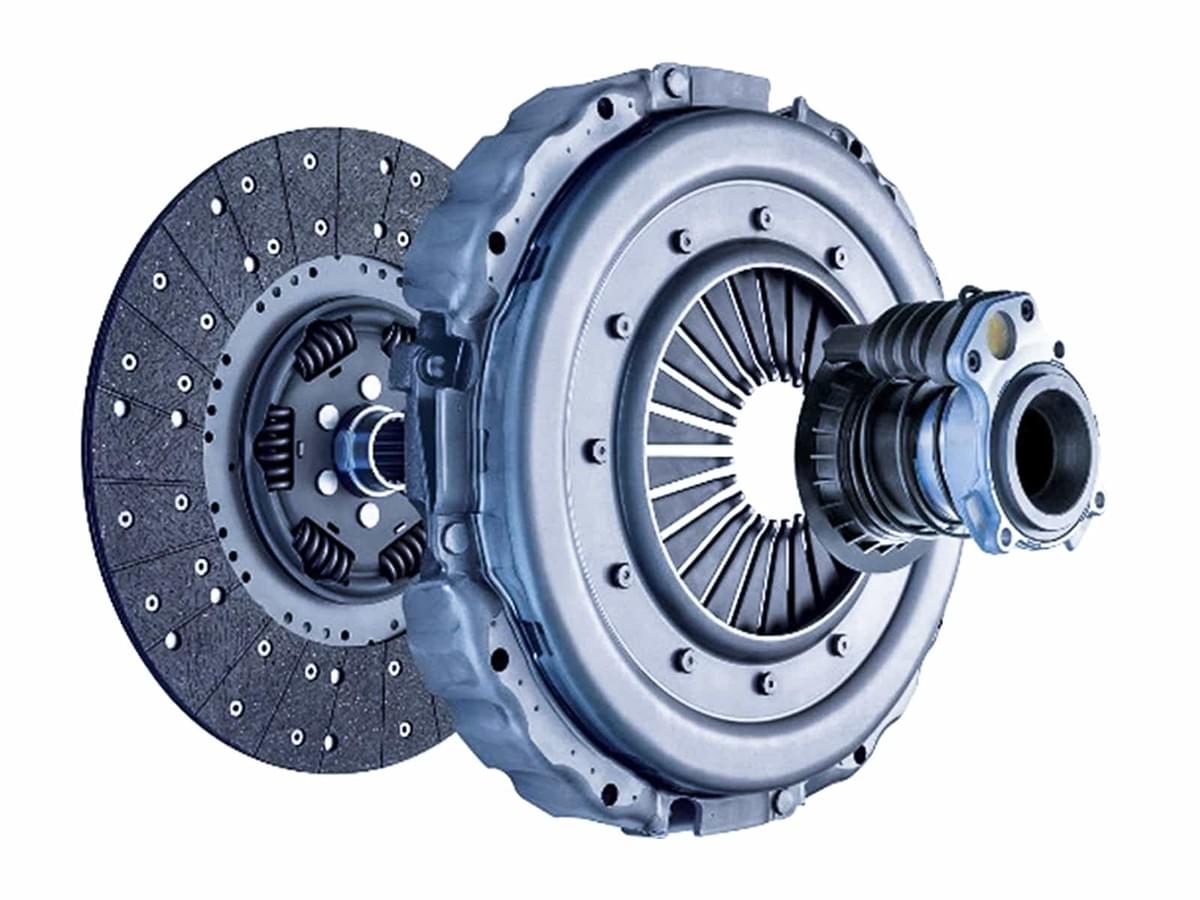

There exist five elements for calculating torque capacity, namely clamp load, coefficient of friction of friction materials, the quantity of surfaces, clutch size and working radius of clutch. At this point, the quantity of surfaces matters, instead of surface area. Thus you can make friction surface very wide, which doesn’t hold any more power but deal with a lot more heat.

In this circumstance, the size is unchanged, as well as the coefficient of friction. Since if friction is increased a lot, drivability will be lost. So if the quantity of surfaces is doubled and others remain same, the torque capacity will be doubled. The clamp load can be lowered so that the pedal can not be too stiff.

Additionally, aluminum clutch ribs are installed with stainless steel sleeves where steel pressure and floater plates ride. This design makes vehicle owner replace the sleeves alone when they are worn out, instead of the entire pressure plate.

But why there isn’t surface area when calculating torque capacity? Because this factor cannot determine it. But it is useful and helpful for heat capacity. With organic material, you would like a full surface, since it can’t deal with the heat like ceramic material. What’s more, the organic material uses resin to bind together. If overheated, the resin will melt. By comparison, ceramic material is heavier and can deal with more heat. At this point, you prefer less material, since if there is a full surface, it will be too heavy and it will deal with considerable amount of heat. Hence you don’t wanna it.

These are reasons why organic materials are full-circumstance discs, but the ceramics use “pucks”.

These clutches need to match specific flywheels which also need to be specific clutch size. Some particular models use these clutches, namely EVO, STI and WRX. In future, more types of clutches will be invented.